In Business Since 1984

Infrared Radiant Heating Basics

What Is Infrared Heat and How Does It Work?

Infrared radiant heating heats in the same manner that the sun warms the earth. The sun’s infrared rays travel through space and our atmosphere with little apparent loss and only convert into heat once they strike the earth, objects, and people. However, infrared is electromagnetic wave energy, so, unlike the sun, infrared heaters do not produce ultraviolet rays—only comfortable radiant warmth similar to standing near a fireplace or stove.

Infrared radiant heating heats in the same manner that the sun warms the earth. The sun’s infrared rays travel through space and our atmosphere with little apparent loss and only convert into heat once they strike the earth, objects, and people. However, infrared is electromagnetic wave energy, so, unlike the sun, infrared heaters do not produce ultraviolet rays—only comfortable radiant warmth similar to standing near a fireplace or stove.

Objects in a building, such as floors, tools, and machinery, absorb the infrared radiant energy as heat energy and create a “heat sink,” where warmth is stored and then reradiated to warm the surrounding air. This translates to warm, comfortable conditions at the occupant floor level and less wasted convective heat at the ceiling. Even buildings with the highest ceilings that are heated with infrared are heated from the floor level up.

Low-intensity infrared tube heaters operate in a temperature range from about 350 to 1,000 degrees Fahrenheit. Corresponding wavelengths are 2 to 10 microns. This is farther away from the visible light spectrum; therefore, no light is emitted, i.e., there is no glow even when the heater is fully on.

A Solaronics infrared heater is remarkably simple in operation as well as maintenance. A burner about the size of a breadbox fueled by either natural gas or propane gas fires a long flame down the first 10-ft. long (4-inch diameter) combustion heat exchanger tube. The burner has a combustion fan that breathes inside building air or, quite commonly, optional outside ducted air for clean operation. This fan pushes the heat down the entire length of the heater. Heater lengths range from 10 ft. to 70 ft. Burner BTU ratings range from 40,000 to 200,000. Two-stage burners are also available with a high and low BTU rating.

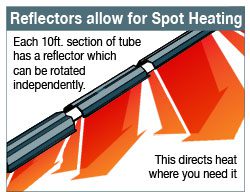

All the heat exchanger tubes have a 16-inch wide aluminum parabolic reflector mounted above to reflect heat downward. The 10-ft. long reflectors can be rotated separately to direct heat where it is needed.

reflector mounted above to reflect heat downward. The 10-ft. long reflectors can be rotated separately to direct heat where it is needed.

The initial burner heat exchanger tube is obviously the hottest, with the end tube being the coolest prior to being ducted to an exhaust termination. Sidewall exhaust flueing is possible, as the burner is forced to draft. The need to exhaust upward through a roof in many heaters is not required.

The result of heating this heat exchanger in this manner is infrared heat that is reflected downwards. Again, this heat is not “released” until it strikes an object. Then, in turn, the object re-radiates and heats the surrounding air. Infrared heaters can be mounted at very high heights but still result in heat re-radiating from the floor level upwards. Typically, a common-style thermostat sensing air temperature controls the infrared heaters.

PO Box 10419

Bedford, NH 03110

Northern New England Phone: (603) 471-1414

CT, NY, NJ Area Phone: (860) 990-0061

info@progressiveenergyinc.com